Khoom

Nyias zaj duab xis getters

Nta thiab Daim Ntawv Thov Cov khoom no yog ib zaj duab xis nyias ntawm titanium los yog zirconium alloy nrog optimized microstructure uas tuaj yeem qhib tau ntau qhov kub thiab txias. Tom qab ua haujlwm, nws tuaj yeem nqus cov pa tsis huv xws li hydrogen, dej vapor, carbon monoxide, carbon dioxide thiab lwm yam impurity ...

Kev piav qhia

Kos npe

Nta thiab Daim Ntawv Thov

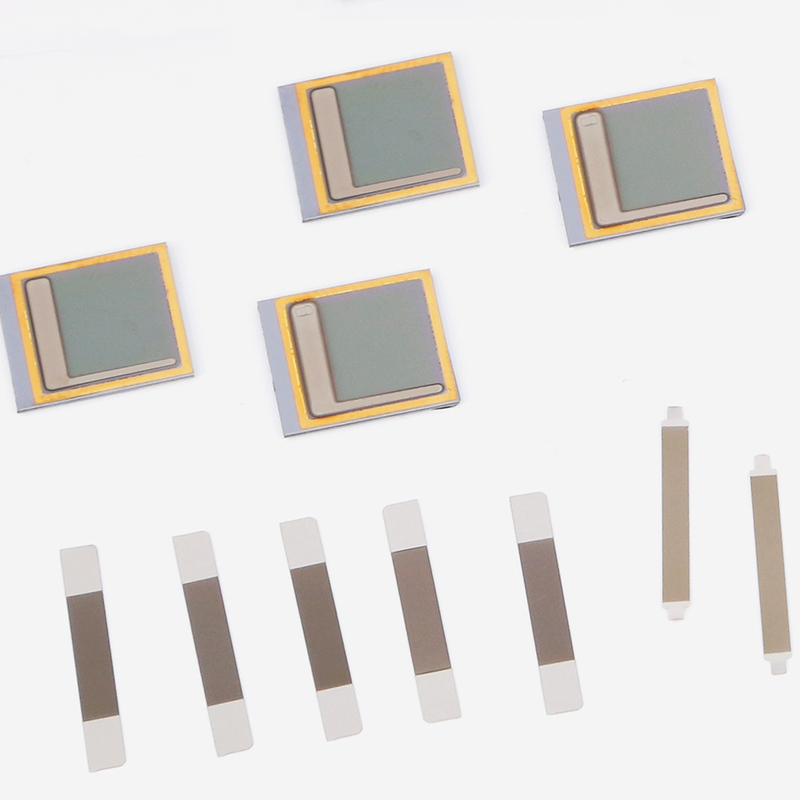

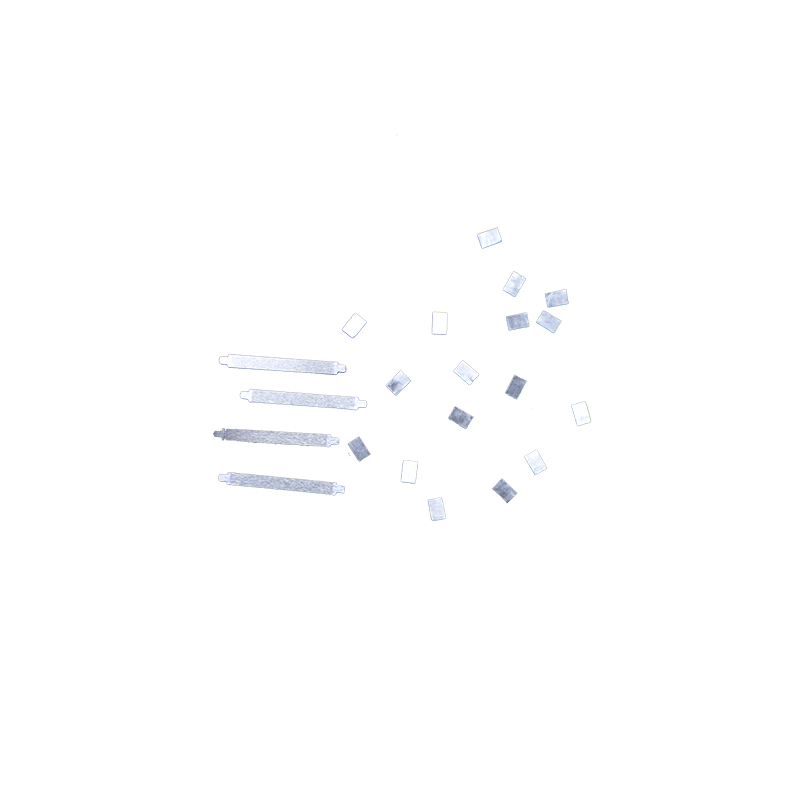

Cov khoom no yog ib zaj duab xis nyias ntawm titanium los yog zirconium alloy nrog optimized microstructure uas tuaj yeem qhib tau ntau qhov kub thiab txias. Tom qab ua kom tiav, nws tuaj yeem nqus cov pa impurity xws li hydrogen, dej vapor, carbon monoxide, carbon dioxide thiab lwm yam impurity gases uas tsis yog cov roj inert hauv lub tshuab nqus tsev, thiab txhim kho thiab tswj lub tshuab nqus tsev hauv lub cuab yeej. Nws muaj cov yam ntxwv ntawm kev tshoov siab loj, tsis muaj cov khoom, thiab qhov kub ua kom qis. Nws tuaj yeem siv dav hauv ntau yam MEMS li xws li uncooled infrared sensors thiab Micro gyroscope. Txawv getter alloys muaj nyob rau txawv txheej txheem encapsulation.

Cov yam ntxwv yooj yim thiab cov ntaub ntawv dav dav

Qauv

Cov qauv zoo ntawm cov khoom yog cov hlau tsis muaj steel nrog lub thickness ntawm 50 microns raws li tus neeg nqa khoom, thiab saum npoo yog coated ntawm ob sab, nrog rau zaj duab xis thickness txog 1.5 microns. Cov duab loj tuaj yeem kho raws li cov neeg siv xav tau. Nws tseem tuaj yeem muab tso rau hauv daim ntawv ntawm cov yeeb yaj kiab nyias ntawm qhov chaw ntawm wafer lossis ntau yam hlau npog daim hlau thiab cov plhaub ceramic.

Sorption Peev xwm

Tom qab cov khoom tau qhib rau hauv lub tshuab nqus tsev siab tsawg dua 1E-3Pa, nws tuaj yeem muaj peev xwm nqus tau, thiab tom qab txias rau chav tsev kub, nws tseem muaj peev xwm adsorb ntau yam khoom siv roj. Raws li qhov ua kom kub nce, lub peev xwm inspiratory maj mam nce. Cov khoom yog rhuab ntawm qhov zoo tshaj plaws ua kom kub rau 30min, thiab lub adsorption muaj peev xwm ntawm CO tom qab txias yog ntau tshaj 0.06Pa · L / cm2. Thaum lub activation kub tshaj qhov zoo tshaj plaws activation kub, ib tug inhalation kev ua tau zoo tom qab txias yog attenuated.

Thaum cov khoom tau qhib los ntawm cua sov hauv lub tshuab nqus tsev qis, cov roj hluav taws xob hauv ib puag ncig pib absorbed thaum lub sij hawm cua sov txheej txheem. Rau cov roj sib txawv, nws qhov nqus nrawm thiab muaj peev xwm sib txawv. Ntawm qhov ntsuas kub thiab nyob rau hauv qhov ntau ntawm tag nrho cov peev txheej nqus tau, qhov pib nqus tau nrawm dua, thiab tom qab ntawd nws yuav ua rau qeeb thiab qeeb; Thaum qhov kub thiab txias tau nce ntxiv, tus nqi nqus tau nce ntxiv thiab tom qab ntawd attenuated dua. Tom qab txias, seb cov khoom puas muaj qhov seem suction muaj peev xwm nyob ntawm seb hom roj active nws absorbs thiab tus nqi ntawm inhalation.

Pom zoo ua kom cov xwm txheej

Rau qhov ua tau zoo tshaj plaws, kev ua kom muaj zog hauv lub tshuab nqus tsev siab tsawg dua 1E-3Pa yog pom zoo, thiab cov kev pom zoo ua kom pom zoo rau txhua cov khoom siv yeeb yaj kiab tau qhia hauv cov npe hauv qab no:

| Cov khoom siv zaj duab xis | Kub thiab sijhawm (℃ × min) |

| TP | 450 × 30 |

| TZC | 300 × 30 |

| TZC | 400 × 30 |

Ceev faj

Cov cua sov tam sim no-ua kom kub kub nkhaus muab nyob rau hauv Cov Khoom Specification yog kuaj los ntawm cov khoom dai rau hauv lub tshuab nqus tsev, thiab qhov tseeb ua kom tam sim no vs. kub nyob ntawm qhov kub poob tom qab cov khoom yog soldered hauv lub cuab yeej. Vim lub tshav kub conduction ntawm vuam txoj hauj lwm, qhov kub ntawm qhov welded ib feem yog qis dua qhov kub ntawm qhov nruab nrab ntawm cov khoom.

Thaum lub sij hawm qhib, tus getter yuav tso tawm sab hauv cov khoom soluble hydrogen. Yog tias muaj dej nyob hauv ib puag ncig, cov pa oxygen hauv dej yuav raug kho los ntawm tus neeg txais, thiab cov khoom siv hydrogen yuav hloov mus rau hydrogen gas kom tso tawm. Nyob rau hauv ib qho chaw kaw, tom qab txias, seb qhov no ntawm cov hydrogen tuaj yeem nqus tau los ntawm tus getter yog nyob ntawm hom thiab cov roj uas nws absorbs thaum ua kom tiav.

tiv tauj peb

Yam khoom nrov

Thov tso lus rau peb.

Thov sau koj email chaw nyob thiab peb yuav teb koj email.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur