produk

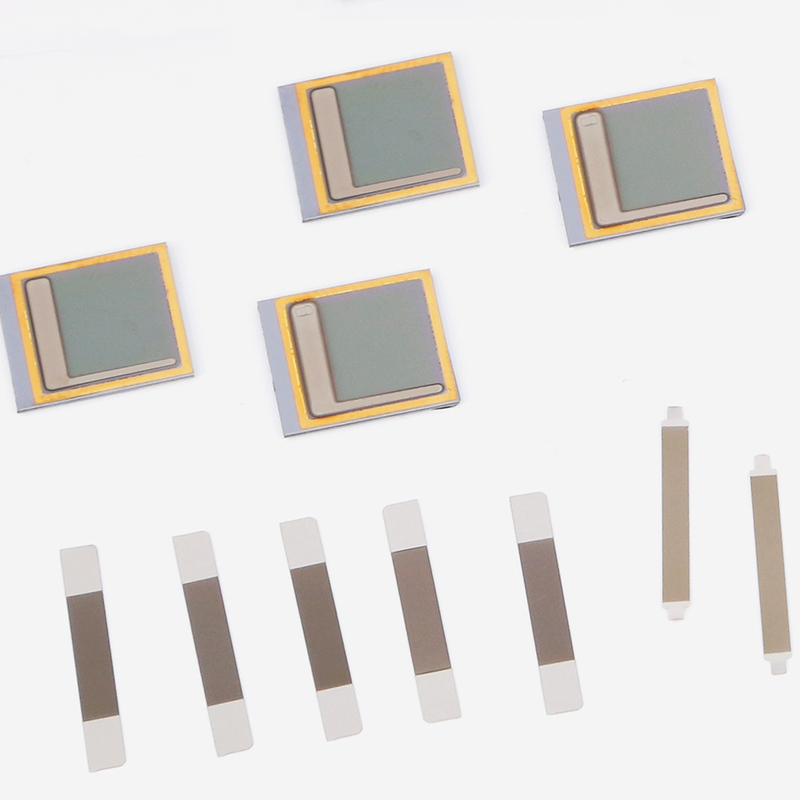

Sintered Porous Getter

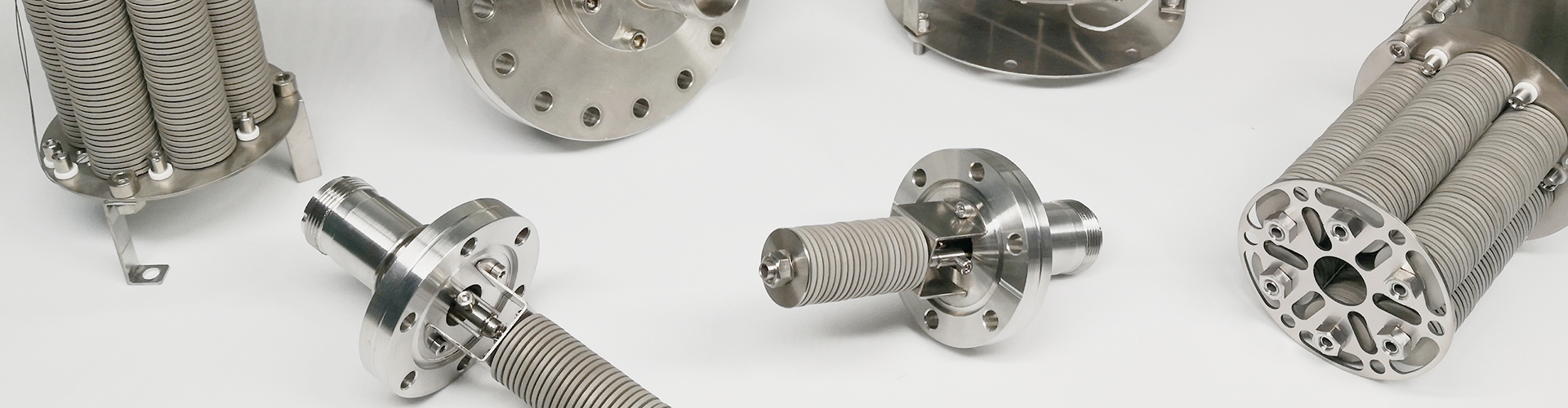

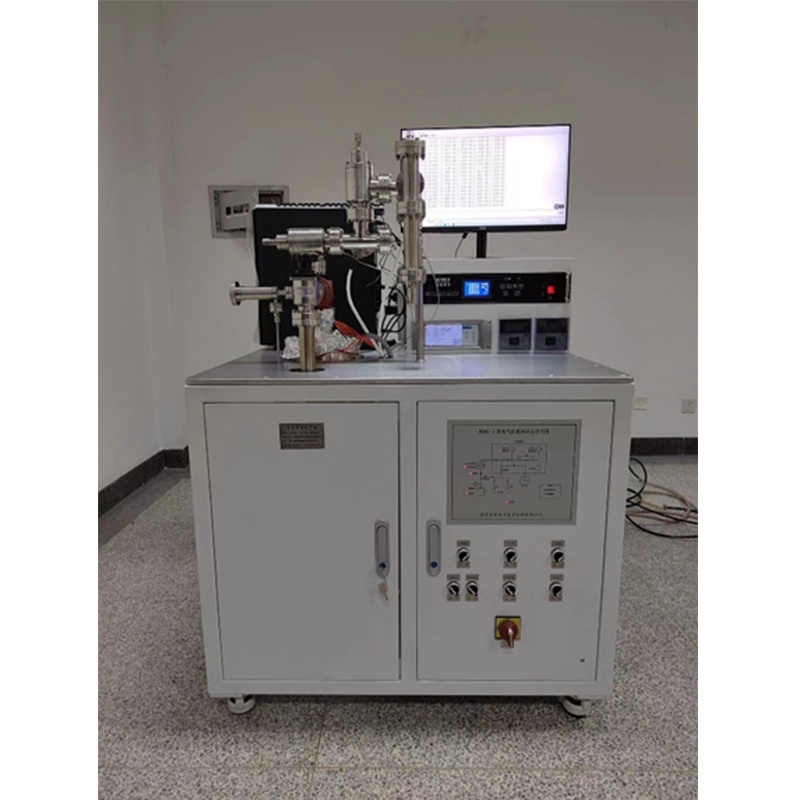

Fitur lan Aplikasi Sintered Porous Getter wis disinter dening kabeh jinis wesi getter non-evaporable ing suhu dhuwur. Punika ditondoi ing suhu aktifitas kurang, tingkat gettering dhuwur, kapasitas sorption amba, compactness apik, lan partikel kurang ngeculke. Kami Sintered Porous Getter i...

Katrangan

mlebu

Fitur lan Aplikasi

Sintered Porous Getter wis disinter dening kabeh jinis wesi getter non-evaporable ing suhu dhuwur. Punika ditondoi ing suhu aktifitas kurang, tingkat gettering dhuwur, kapasitas sorption amba, compactness apik, lan partikel kurang ngeculke. Sintered Porous Getter kita ditambahake karo aktivator efisiensi dhuwur lan agen anti-sintering supaya bisa nambah kinerja gettering. Ukuran lan wangune bisa digawe miturut syarat pelanggan. Uga bisa nggawa pemanas supaya bisa digunakake ing ngendi ora bisa diaktifake kanthi frekuensi dhuwur utawa radiasi panas. Getter ditrapake kanggo detektor IR Dewar, tabung X-Ray, lan liya-liyane.

Karakteristik dhasar lan Data Umum

1. Ora ana jinis pemanas

| Jinis | OD (mm) | L. D. (mm) | H (mm) | Njelaske nganggo bentuk garis |

| TM7D260X | 6.9 | 3.1 | 3.1 | PIC 1 |

| TM8D150X | 7.9 | 3.6 | 1.25 | PIC 1 |

| TM8D240X | 8 | 2 | 1.8 | PIC 1 |

| TM10D620X | 9.9 | 4.9 | 3.6 | PIC 1 |

| TM10D660X | 10.5 | 6.1 | 3.85 | PIC 1 |

| TM10D710X | 10 | 6.1 | 4.9 | PIC 1 |

| TM12D360X | 12 | 8 | 2 | PIC 1 |

| TM12D450X | 11.9 | 5.3 | 1.7 | PIC 1 |

| TM12D720X | 12 | 8 | 4 | PIC 1 |

| TM12D940X | 12.35 | 7.1 | 3.9 | PIC 1 |

| TM13D1030X | 12.6 | 8.8 | 5.5 | PIC 1 |

| TM13D1880X | 12.5 | 5.9 | 7.6 | PIC 1 |

| TM15D400X | 14.9 | 9.1 | 1.3 | PIC 1 |

| TM15D950X | 15 | 10 | 3.5 | PIC 1 |

| TM15D1300X | 15 | 8.5 | 3.9 | PIC 1 |

| TM15D1420X | 15 | 8.5 | 4 | PIC 1 |

| TM15P1480X | 15 | / | 4 | PIC 2 |

| TM16D870X | 15.8 | 5.3 | 1.7 | PIC 1 |

| TM18D2350X | 17.9 | 8.1 | 4 | PIC 1 |

| TM19D2250X | 19 | 10.2 | 3.8 | PIC 1 |

| TM20D1410X | 20 | 6.3 | 1.7 | PIC 1 |

| TM21D1250X | 21 | 15 | 2.5 | PIC 1 |

| TM21D2200X | 21 | 14 | 4 | PIC 1 |

| TM25D1930X | 24.9 | 6.2 | 1.7 | PIC 1 |

| TM25D5700X | 24.8 | 14.2 | 6 | PIC 1 |

| TM26D7780X | 25.85 | 10.2 | 6 | PIC 1 |

| TM28D6820X | 27.6 | 14.3 | 5.3 | PIC 1 |

| TM32D6650X | 31.7 | 21.3 | 6 | PIC 1 |

| TM45D8000X | 45 | 39 | 10 | PIC 1 |

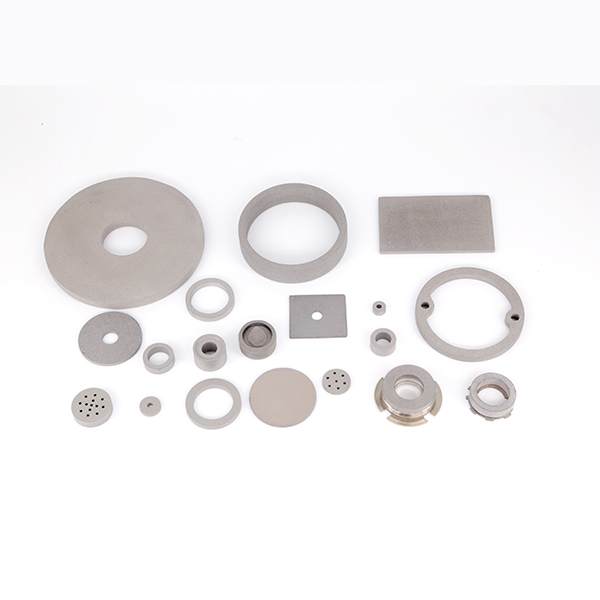

2. Kanthi jinis Heater

| Jinis | Paduan | OD (mm) | L2 (mm) | L1 (mm) | Njelaske nganggo bentuk garis |

| ZZV1IM10H-C | Zr/Zr-V-Fe | 1 | 4 | 12 | PIC 3 |

| ZZV2IM40H-C | Zr/Zr-V-Fe | 2 | 4 | 10 | PIC 3 |

| ZZV2IM70H-C | Zr/Zr-V-Fe | 1.85 | 7.9 | 20 | PIC 3 |

| ZZV2IM70HTL-C | Zr/Zr-V-Fe | 1.8 | 7.4 | 18 | PIC 4 |

| ZZV3IM100H-C | Zr/Zr-V-Fe | 2.9 | 6.65 | 20.5 | PIC 4 |

| ZZV3IM150H-C | Zr/Zr-V-Fe | 3.3 | 7.8 | 20.5 | PIC 4 |

| ZZV3IM150H-CK | Zr/Zr-V-Fe | 3 | 7.1 | 17 | PIC 4 |

| ZZV4IM290H-C | Zr/Zr-V-Fe | 4 | 7.9 | 17 | PIC 4 |

| ZZV4IM290H-CB | Zr/Zr-V-Fe | 4 | 7.1 | 17 | PIC 4 |

| ZZV4IM290H-CK | Zr/Zr-V-Fe | 4 | 7.8 | 17 | PIC 4 |

| ZZV7DM650UT-C | Zr/Zr-V-Fe | 7.8 | 5.5 | 18.5 | PIC 7 |

| TM8DM800U | Ti / Mo | 8.4 | 8.5 | 22 | PIC 5 |

| ZZV8DM1000U-C | Zr/Zr-V-Fe | 8.2 | 9 | 17.5 | PIC 5 |

| ZZV8DIM1000I-C | Zr/Zr-V-Fe | 8.3 | 8.1 | 15.5 | PIC 6 |

| ZZV10DM1200UT-C | Zr/Zr-V-Fe | 10 | 10.4 | 23.5 | PIC 7 |

| TM14DM1800U | Ti / Mo | 14.2 | 9 | 21 | PIC 5 |

| ZZ14DM2100U | Zr/ZrAl | 14.2 | 9 | 21 | PIC 5 |

| ZZ14DM2100U-C | Zr/ZrAl | 14.2 | 9 | 21 | PIC 5 |

| ZZ14DM2100U-C2 | Zr/ZrAl | 14.2 | 9 | 21 | PIC 5 |

| ZZV14DM2800U-C | Zr/Zr-V-Fe | 14.2 | 9 | 21 | PIC 5 |

| ZZV16DM5000U-C | Zr/Zr-V-Fe | 16 | 10 | 17 | PIC 5 |

| ZZV20DM1200U-C | Zr/Zr-V-Fe | 20 | 3.5 | PIC 9 | |

| ZZV22DM2700U-C | Zr/Zr-V-Fe | 22 | 7 | PIC 8 | |

| ZZV26DM3200U-C | Zr/Zr-V-Fe | 26 | 4.5 | PIC 10 |

Kondisi aktivasi sing disaranake

| Paduan | Aktifake Suhu ℃ | Suhu Operasi ℃ | Kurva Sorpsi Khas |

| Zr / Zr-V-Fe | 400 - 800 | Suhu Kamar 300 | Grafik 1 |

| Ti / Mo | 400 - 800 | Suhu Kamar 300 | Grafik 2 |

| Zr / ZrAl | 700 - 900 | Suhu Kamar 300 | Grafik 3 |

Grafik1: Kurva Penyerapan Khas saka Zr / Zr-V-Fe

Aktivasi: 500 ℃ × 10 min Serep: H2, 25℃, P=4×10-4Pa

Grafik2: Kurva Penyerapan Khas Ti / Mo

Aktivasi: 500 ℃ × 10 min Penyerapan: H2, 25℃, P=4×10-4Pa

Grafik3: Kurva Penyerapan Khas Zr / ZrAl

Aktivasi: 900 ℃ × 10 min Sorption: H2,25℃, P=4×10-4Pa

Ati-ati

1. Getter sing disegel kudu disimpen ing lingkungan garing sing resik kanthi kelembapan relatif luwih murah tinimbang 75% m lan ora ana gas erosif.

2. Getter stabil ing udhara, nanging bledug, uap lan gas erosif kudu nyingkiri. Kanggo ngumpulake getter, sarung tangan serat dilarang lan sarung tangan lateks sing bisa dibuang dianjurake.

3. Getter bakal digunakake ing wektu sawise tas aluminium foil utawa bisa unsealed.

4. Suhu getter ora kudu luwih saka 200 ℃ ing udhara, yen ora bakal mateni dhewe.

5. Dhukungan saka mesin ingkang ndamel benter getter ora goyangake banget, lan kudu ati-ati nalika welding getter supaya tiba-mati saka wesi getter. Perhatian khusus kudu dibayar kanggo ngindhari kontak langsung ing antarane timbal metalik sing gundhul lan bahan getter ing endi timbal mlebu ing awak getter: nyatane iki bakal nyebabake sirkuit cendhak sing mbebayani.

6. Getter bisa nindakake mung sawise diaktifake. Biasane, disaranake aktivasi sadurunge nutup piranti lan piranti bakal disegel sawise getter diaktifake. Sajrone wektu urip piranti, getter bisa diaktifake maneh.

7. Wektu jaminan kualitas kanggo getter sing disegel yaiku setaun saka tanggal manufaktur.

hubungi kita

Produk populer sing gegandhengan

Mangga ninggalake kita pesen.

Mangga ketik alamat email sampeyan lan kita bakal mbales email sampeyan.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur