Understanding and Applying Sintered Getters

2025-04-24

Understanding and Applying Sintered Getters

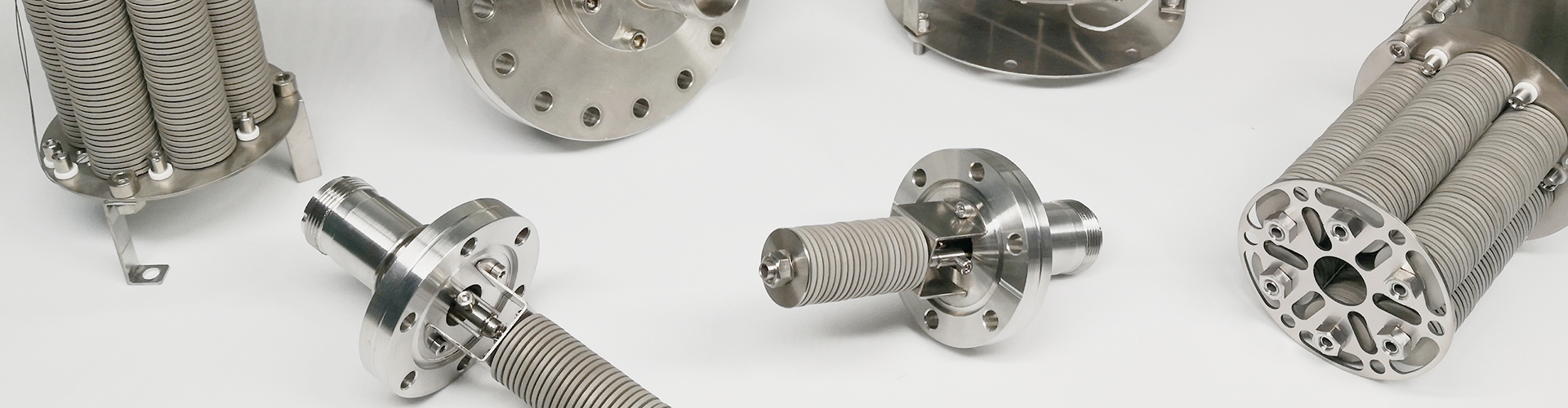

This comprehensive guide explores the world of sintered getters, covering their fundamental principles, diverse applications, and selection criteria. We will delve into the material science behind these crucial components, examining their performance characteristics and providing practical insights for engineers and researchers. Learn how to choose the right sintered getter for your specific vacuum application and optimize its effectiveness.

What are Sintered Getters?

Sintered getters are porous materials designed to absorb gases within a vacuum environment. They play a vital role in maintaining ultra-high vacuum (UHV) conditions, crucial for numerous applications across various industries. These materials typically consist of a metallic powder, such as zirconium-aluminum alloy, that is processed through sintering to create a porous structure with a high surface area. This large surface area allows for efficient gas adsorption, making them essential for ensuring the cleanliness and integrity of vacuum systems. The effectiveness of a sintered getter hinges on its ability to chemically react with or adsorb residual gases, thereby removing them from the vacuum chamber. Different sintered getter materials exhibit varying affinities for different gases, allowing for tailored solutions based on specific requirements.

Types of Sintered Getters and Their Applications

Several types of sintered getters exist, each possessing unique properties and applications. The selection of the appropriate sintered getter depends heavily on the specific vacuum system’s operational parameters and the types of gases to be removed.

Zirconium-Aluminum Alloy Getters

Zirconium-aluminum (ZrAl) alloy sintered getters are among the most commonly used. Their exceptional reactivity with various gases, including oxygen, nitrogen, hydrogen, and carbon monoxide, makes them ideal for various vacuum applications. They are often employed in vacuum tubes, electron tubes, and other vacuum-based devices. Their relatively high gettering capacity and good thermal stability contribute to their widespread use. Nanjing Huadong Electronics Vacuum Material Co., Ltd offers a comprehensive range of high-quality ZrAl sintered getters.

Other Getter Materials

Besides ZrAl alloys, other materials can be used to create sintered getters, each with its own advantages and disadvantages. These include, but aren’t limited to, titanium, tantalum, and various alloys optimized for specific gases or operating conditions. The choice often involves balancing factors like cost, effectiveness, and operating temperature.

Factors Affecting Getter Performance

Several factors influence the effectiveness of a sintered getter. These include:

Temperature

The operating temperature significantly impacts the gettering efficiency. Higher temperatures generally enhance the rate of gas absorption. However, excessively high temperatures can compromise the getter’s structural integrity. Choosing a sintered getter with an appropriate temperature rating is crucial for optimal performance and longevity.

Surface Area

A larger surface area allows for more efficient gas absorption. The sintering process plays a critical role in controlling the porosity and ultimately the surface area of the getter. Manufacturers carefully optimize this process to maximize gettering performance.

Gas Composition

The type and partial pressures of gases present in the vacuum system dictate the gettering rate and overall effectiveness. Some sintered getters are more effective at removing specific gases than others. Careful consideration of the gas composition is essential for optimal getter selection.

Selection Guide for Sintered Getters

| Parameter | Considerations |

|---|---|

| Gas Composition | Identify the primary gases to be removed. This determines the appropriate getter material. |

| Operating Temperature | Choose a getter with a temperature rating compatible with the vacuum system’s operating conditions. |

| Required Gettering Capacity | Calculate the required gettering capacity based on the system’s volume and gas load. |

| Vacuum System Design | Consider the getter’s physical dimensions and its compatibility with the vacuum chamber’s geometry. |

Selecting the correct sintered getter is critical for ensuring the long-term performance and reliability of any vacuum system. Careful consideration of the factors outlined above will help in making an informed decision. For high-quality sintered getters and expert advice, contact Nanjing Huadong Electronics Vacuum Material Co., Ltd.

Please leave us a message.

Please enter your email address and we will reply to your email.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur