Understanding and Applying Sintered Porous Getters

2025-04-24

Understanding and Applying Sintered Porous Getters

This comprehensive guide explores sintered porous getters, their applications, and key considerations for effective implementation. We’ll delve into the science behind their functionality, explore various types available, and discuss best practices for selection and integration.

What are Sintered Porous Getters?

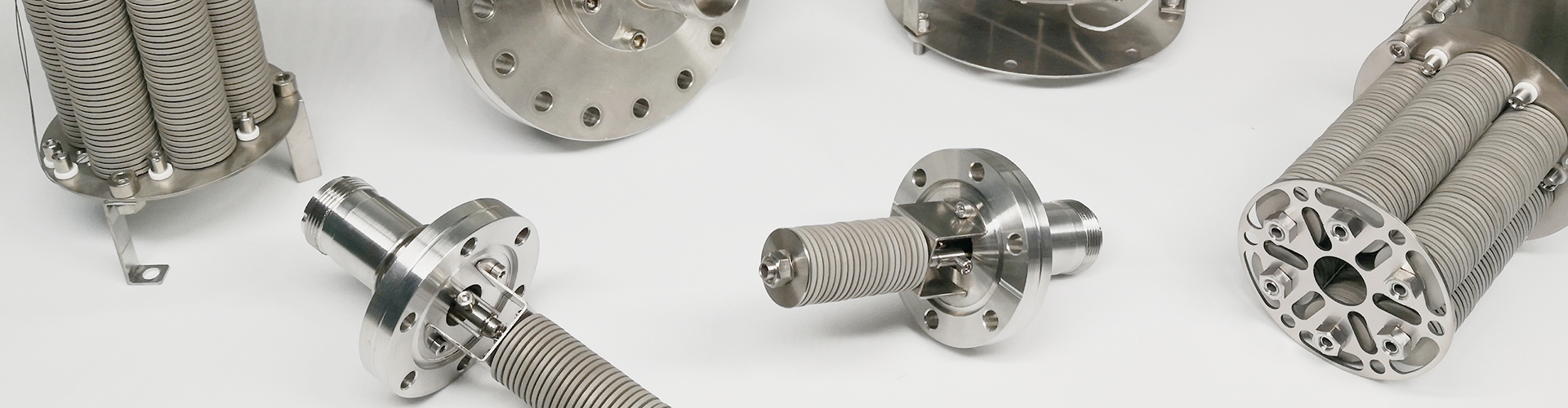

Sintered porous getters are materials engineered to absorb gases and impurities from a vacuum environment. Their porous structure provides a large surface area for efficient gas capture, making them crucial for maintaining ultra-high vacuum (UHV) conditions in various applications. This process, known as gettering, is vital for numerous industries including electronics, aerospace, and scientific research. The high porosity allows for efficient diffusion of gases into the bulk material where they are chemically or physically trapped. The material itself is typically manufactured through powder metallurgy techniques, resulting in a durable and effective gas-absorbing material. The effectiveness and longevity of a sintered porous getter depend heavily on the material composition, its porosity, and the specific gases it’s designed to absorb.

Types of Sintered Porous Getters

Several materials are used in the creation of sintered porous getters, each with its own strengths and weaknesses. Common materials include:

1. Non-Evaporable Getters (NEG)

NEGs, such as those based on Zr-V-Fe alloys, are a widely used type of sintered porous getter. They are known for their high capacity to absorb gases like oxygen, nitrogen, hydrogen, and carbon monoxide. NEGs are particularly useful in maintaining UHV conditions over extended periods, making them ideal for long-term vacuum applications. Their resistance to evaporation even at elevated temperatures distinguishes them from evaporable getters.

2. Evaporable Getters

While less common in sintered porous form, evaporable getters are sometimes incorporated into systems. These getters vaporize and coat internal surfaces to increase their gas-absorbing capacity. They’re often used in conjunction with NEGs to provide an initial rapid cleanup of the vacuum environment. However, they might not be suitable for all applications due to the potential for contamination from the evaporating material.

Applications of Sintered Porous Getters

Sintered porous getters find applications in a diverse range of industries and technologies:

1. Vacuum Tubes and Devices

Maintaining a high vacuum is crucial for the proper functioning of many vacuum tubes and devices. Sintered porous getters are widely used to remove residual gases, ensuring optimal performance and longevity.

2. Vacuum Furnaces and Chambers

In high-temperature processes requiring vacuum environments, sintered porous getters are essential for removing impurities and maintaining the desired pressure. This is critical for many industrial processes such as thin-film deposition and material processing.

3. Spacecraft and Satellites

The ultra-high vacuum environments of space necessitate the use of high-performance sintered porous getters to remove outgassed components from spacecraft and satellite systems. This ensures the reliable operation of sensitive instruments and equipment.

Choosing the Right Sintered Porous Getter

The selection of a suitable sintered porous getter depends on several factors, including the specific gases to be removed, the required vacuum level, the operating temperature, and the overall system design. Consulting with a specialist is recommended to determine the optimal solution for your application.

Sintered Porous Getter Specifications Comparison

| Getter Type | Material | Gas Absorption Capacity | Operating Temperature Range (°C) |

|---|---|---|---|

| NEG | Zr-V-Fe | High | Wide range |

| Evaporable | Various (e.g., Ti, Ba) | Moderate to High | Dependent on material |

Note: Specific data may vary depending on the manufacturer and product specifications. For detailed information, consult product datasheets from reputable suppliers such as Nanjing Huadong Electronics Vacuum Material Co., Ltd.

Conclusion

Sintered porous getters are essential components in various vacuum systems, providing efficient and reliable gas absorption capabilities. Understanding the different types, applications, and selection criteria is crucial for successful implementation in a wide range of technologies. Always consult with a specialist and review relevant datasheets to ensure compatibility and optimal performance.

Please leave us a message.

Please enter your email address and we will reply to your email.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur