Understanding and Utilizing Sintered Porous Getters

2025-04-21

Understanding and Utilizing Sintered Porous Getters

This comprehensive guide explores the intricacies of sintered porous getters, covering their functionality, applications, advantages, and considerations for selection. We delve into the material science behind these devices, providing practical insights for engineers and technicians working with vacuum technologies.

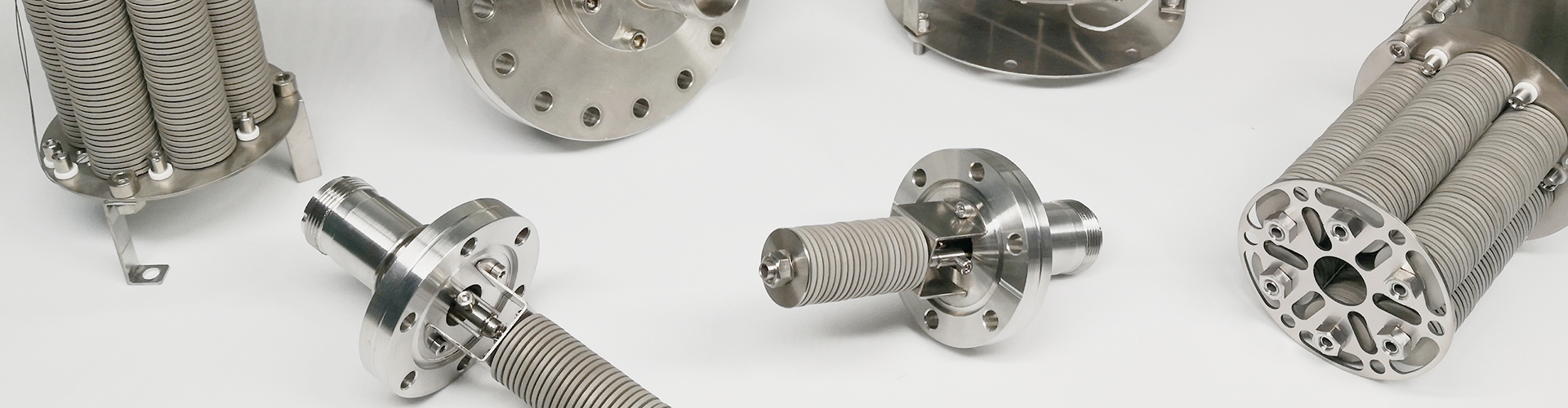

What are Sintered Porous Getters?

Sintered porous getters are specialized materials designed to absorb gases and impurities from vacuum systems. Their porous structure, typically made from metals such as zirconium-aluminum (ZrAl) alloys or titanium-aluminum (TiAl) alloys, provides a large surface area for gas adsorption. This adsorption process occurs through chemical reactions, effectively cleaning and maintaining a high vacuum within the system. The sintering process creates a robust and durable structure, capable of withstanding high temperatures and pressures. Nanjing Huadong Electronics Vacuum Material Co., Ltd. (https://www.hddzgetters.com/) is a leading manufacturer of high-quality sintered porous getters, offering a wide range of solutions for various applications.

Types and Materials of Sintered Porous Getters

ZrAl Getters

Zirconium-aluminum (ZrAl) sintered porous getters are widely used due to their high gettering capacity for active gases like oxygen, nitrogen, and hydrogen. They are known for their excellent reactivity and relatively low activation temperature. The specific composition of the ZrAl alloy can be tailored to optimize performance for particular gas types and operating conditions.

TiAl Getters

Titanium-aluminum (TiAl) sintered porous getters offer similar functionalities to ZrAl getters but may exhibit different reactivity profiles. They can be particularly effective in certain applications, offering a suitable alternative depending on the specific requirements of the vacuum system. The selection between ZrAl and TiAl often depends on factors such as the type of gases to be removed, the operating temperature, and the desired lifetime of the getter.

Applications of Sintered Porous Getters

Sintered porous getters find applications in a diverse range of industries, including:

- Vacuum tubes and devices

- High-vacuum systems in research and development

- Spacecraft and satellite instrumentation

- Medical and analytical equipment

- Electron microscopes and other scientific instruments

Their ability to maintain ultra-high vacuum conditions is critical for the proper functioning of these systems, preventing degradation and improving reliability.

Advantages of Using Sintered Porous Getters

The benefits of utilizing sintered porous getters include:

- High gas absorption capacity

- Effective removal of active gases

- Long operational lifetime

- Robust and durable construction

- Ease of integration into vacuum systems

Selecting the Right Sintered Porous Getter

Choosing the appropriate sintered porous getter requires careful consideration of several factors, including the specific gases to be removed, the operating temperature range, and the required vacuum level. Consulting with a specialist from a reputable manufacturer, like Nanjing Huadong Electronics Vacuum Material Co., Ltd., can ensure optimal performance and longevity.

Comparison of Getter Materials

| Property | ZrAl Getter | TiAl Getter |

|---|---|---|

| Gettering Capacity | High | High |

| Activation Temperature | Relatively Low | Moderate |

| Gas Reactivity | Excellent for O2, N2, H2 | Good for O2, N2, H2; May vary depending on the specific alloy |

Note: Specific data may vary depending on the manufacturer and the specific alloy composition. Consult datasheets from reputable manufacturers for precise information.

Please leave us a message.

Please enter your email address and we will reply to your email.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur