Understanding and Utilizing Zirconium Getters

2025-04-23

Understanding and Utilizing Zirconium Getters

This comprehensive guide explores the world of zirconium getters, detailing their function, applications, and selection criteria. Learn about the different types of zirconium getters, their advantages and disadvantages, and how to choose the right getter for your specific vacuum application. We’ll delve into the underlying chemistry and physics, providing practical insights for engineers and technicians working with vacuum systems.

What are Zirconium Getters?

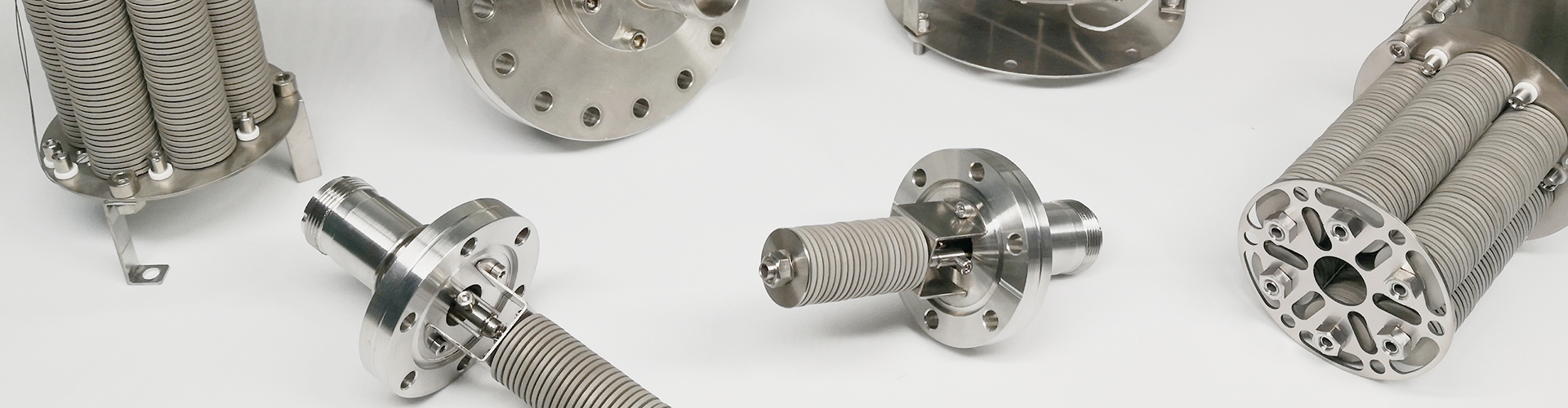

Zirconium getters are materials used in vacuum systems to remove residual gases, improving the overall vacuum quality. They achieve this through a process called gettering, where the zirconium chemically reacts with and absorbs gases such as oxygen, nitrogen, hydrogen, and carbon monoxide. The effectiveness of a zirconium getter depends on several factors, including its surface area, purity, and the operating temperature. Nanjing Huadong Electronics Vacuum Material Co., Ltd. (https://www.hddzgetters.com/) is a leading manufacturer of high-quality zirconium getters, offering a wide range of options to meet diverse application needs. Their expertise in this field ensures reliable performance and longevity in vacuum systems.

Types of Zirconium Getters

Non-Evaporable Getters (NEG)

NEG zirconium getters are commonly used due to their robust nature and ability to operate at room temperature. These getters are typically made of a zirconium alloy, often with vanadium or other elements added to enhance their gettering capacity. They are often used in sealed vacuum devices where high-temperature activation is impractical. The unique properties of NEG zirconium getters allow for long-term gas absorption, contributing to the sustained performance of the vacuum system.

Evaporable Getters

Evaporable zirconium getters require high-temperature activation, which vaporizes the zirconium and deposits it as a thin film on the internal surfaces of the vacuum chamber. This increases the overall surface area available for gas absorption, resulting in high pumping speeds. This method is suitable for applications requiring rapid and effective gas removal. However, the high-temperature activation process requires careful control and consideration of thermal stress on other components of the vacuum system.

Choosing the Right Zirconium Getter

Selecting the appropriate zirconium getter depends heavily on your specific application requirements. Factors to consider include:

- The desired ultimate vacuum pressure

- The types and amounts of gases to be removed

- The operating temperature of the vacuum system

- The required lifetime of the getter

- The size and geometry of the vacuum chamber

Applications of Zirconium Getters

Zirconium getters find extensive use across numerous industries, including:

- Vacuum tubes

- Electron tubes

- Incandescent lamps

- Scientific instruments

- Spacecraft components

Advantages and Disadvantages of Zirconium Getters

| Feature | Advantages | Disadvantages |

|---|---|---|

| Effectiveness | High gas absorption capacity | Can be limited by surface area |

| Cost | Relatively inexpensive compared to other getter technologies | Cost can vary depending on type and purity |

| Activation | Some types are easily activated | Some types require high-temperature activation |

Conclusion

Zirconium getters are essential components in many vacuum systems, offering effective and reliable gas removal. Understanding the different types, applications, and selection criteria is crucial for ensuring the optimal performance of your vacuum system. By carefully considering the factors discussed above, you can select the most suitable zirconium getter for your specific application, leading to improved vacuum quality and system longevity. Remember to consult with experts like Nanjing Huadong Electronics Vacuum Material Co., Ltd. for assistance in selecting the appropriate zirconium getter for your specific needs.

Please leave us a message.

Please enter your email address and we will reply to your email.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur