produk

Sintered porous Getter

Fitur sarta Aplikasi Sintered Porous Getter ieu sintered ku sagala jinis alloy getter non-evaporable dina suhu luhur. Hal ieu dicirikeun dina suhu aktivasina low, laju gettering tinggi, kapasitas sorption badag, compactness alus, sarta partikel kirang leupas. Kami Sintered Porous Getter i...

Katerangan

asup

Fitur sarta Aplikasi

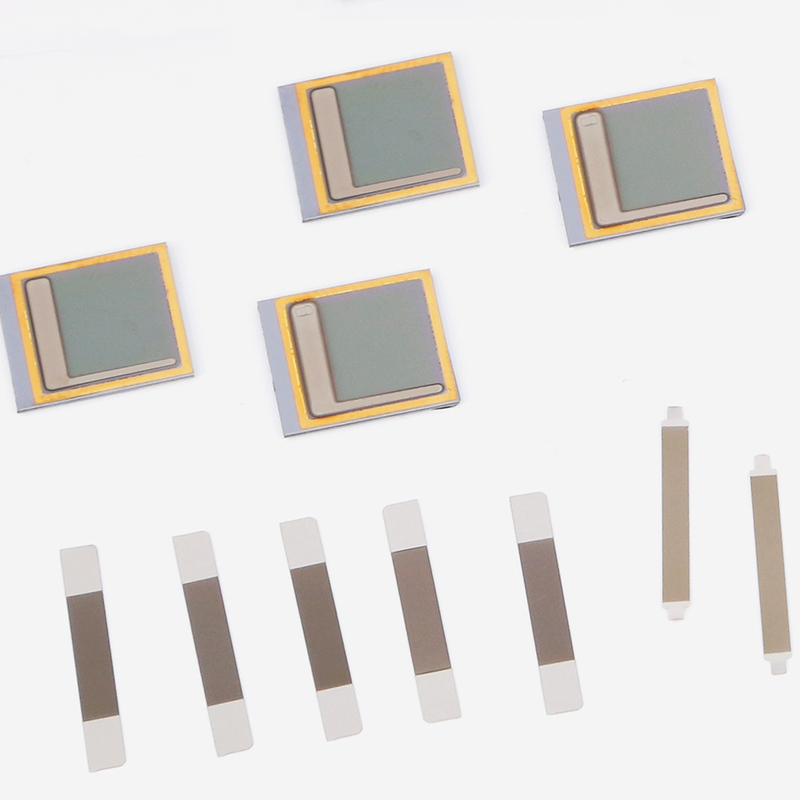

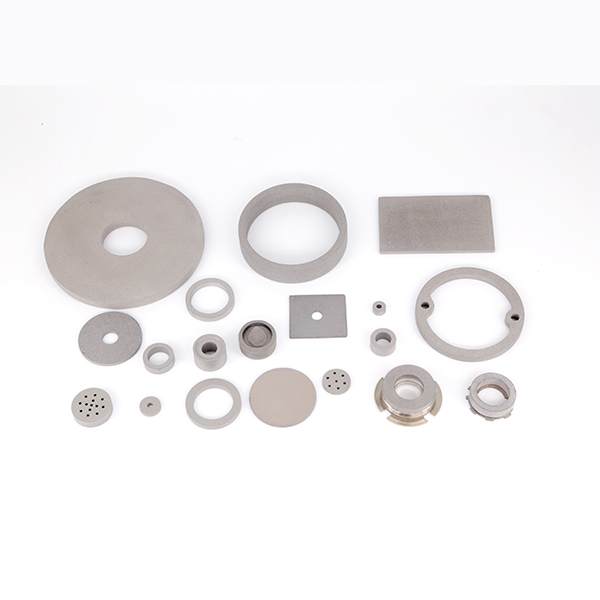

Sintered Porous Getter disinter ku sagala jinis alloy getter non-evaporable dina suhu luhur. Hal ieu dicirikeun dina suhu aktivasina low, laju gettering tinggi, kapasitas sorption badag, compactness alus, sarta partikel kirang leupas. Sintered Porous Getter kami ditambahan ku aktivator efisiensi tinggi sareng agén anti-sintering supados ningkatkeun kamampuan gettering na. Ukuran sarta bentukna bisa dijieun nurutkeun sarat konsumén '. Éta ogé tiasa nyandak manaskeun supados tiasa dianggo dimana éta henteu tiasa diaktipkeun ku frekuensi tinggi atanapi radiasi panas. Getter diterapkeun kana detektor IR Dewar, tabung X-Ray, sareng saterasna.

Karakteristik Dasar jeung Data Umum

1.No Tipe manaskeun

| Tipe | OD (mm) | L.D. (mm) | H (mm) | Outlines |

| TM7D260X | 6.9 | 3.1 | 3.1 | PIC 1 |

| TM8D150X | 7.9 | 3.6 | 1.25 | PIC 1 |

| TM8D240X | 8 | 2 | 1.8 | PIC 1 |

| TM10D620X | 9.9 | 4.9 | 3.6 | PIC 1 |

| TM10D660X | 10.5 | 6.1 | 3.85 | PIC 1 |

| TM10D710X | 10 | 6.1 | 4.9 | PIC 1 |

| TM12D360X | 12 | 8 | 2 | PIC 1 |

| TM12D450X | 11.9 | 5.3 | 1.7 | PIC 1 |

| TM12D720X | 12 | 8 | 4 | PIC 1 |

| TM12D940X | 12.35 | 7.1 | 3.9 | PIC 1 |

| TM13D1030X | 12.6 | 8.8 | 5.5 | PIC 1 |

| TM13D1880X | 12.5 | 5.9 | 7.6 | PIC 1 |

| TM15D400X | 14.9 | 9.1 | 1.3 | PIC 1 |

| TM15D950X | 15 | 10 | 3.5 | PIC 1 |

| TM15D1300X | 15 | 8.5 | 3.9 | PIC 1 |

| TM15D1420X | 15 | 8.5 | 4 | PIC 1 |

| TM15P1480X | 15 | / | 4 | PIC 2 |

| TM16D870X | 15.8 | 5.3 | 1.7 | PIC 1 |

| TM18D2350X | 17.9 | 8.1 | 4 | PIC 1 |

| TM19D2250X | 19 | 10.2 | 3.8 | PIC 1 |

| TM20D1410X | 20 | 6.3 | 1.7 | PIC 1 |

| TM21D1250X | 21 | 15 | 2.5 | PIC 1 |

| TM21D2200X | 21 | 14 | 4 | PIC 1 |

| TM25D1930X | 24.9 | 6.2 | 1.7 | PIC 1 |

| TM25D5700X | 24.8 | 14.2 | 6 | PIC 1 |

| TM26D7780X | 25.85 | 10.2 | 6 | PIC 1 |

| TM28D6820X | 27.6 | 14.3 | 5.3 | PIC 1 |

| TM32D6650X | 31.7 | 21.3 | 6 | PIC 1 |

| TM45D8000X | 45 | 39 | 10 | PIC 1 |

2.With manaskeun Tipe

| Tipe | Paduan | OD (mm) | L2 (mm) | L1 (mm) | Outlines |

| ZZV1IM10H-C | Zr/Zr-V-Fe | 1 | 4 | 12 | PIC 3 |

| ZZV2IM40H-C | Zr/Zr-V-Fe | 2 | 4 | 10 | PIC 3 |

| ZZV2IM70H-C | Zr/Zr-V-Fe | 1.85 | 7.9 | 20 | PIC 3 |

| ZZV2IM70HTL-C | Zr/Zr-V-Fe | 1.8 | 7.4 | 18 | PIC 4 |

| ZZV3IM100H-C | Zr/Zr-V-Fe | 2.9 | 6.65 | 20.5 | PIC 4 |

| ZZV3IM150H-C | Zr/Zr-V-Fe | 3.3 | 7.8 | 20.5 | PIC 4 |

| ZZV3IM150H-CK | Zr/Zr-V-Fe | 3 | 7.1 | 17 | PIC 4 |

| ZZV4IM290H-C | Zr/Zr-V-Fe | 4 | 7.9 | 17 | PIC 4 |

| ZZV4IM290H-CB | Zr/Zr-V-Fe | 4 | 7.1 | 17 | PIC 4 |

| ZZV4IM290H-CK | Zr/Zr-V-Fe | 4 | 7.8 | 17 | PIC 4 |

| ZZV7DM650UT-C | Zr/Zr-V-Fe | 7.8 | 5.5 | 18.5 | PIC 7 |

| TM8DM800U | Ti/Mo | 8.4 | 8.5 | 22 | PIC 5 |

| ZZV8DM1000U-C | Zr/Zr-V-Fe | 8.2 | 9 | 17.5 | PIC 5 |

| ZZV8DIM1000I-C | Zr/Zr-V-Fe | 8.3 | 8.1 | 15.5 | PIC 6 |

| ZZV10DM1200UT-C | Zr/Zr-V-Fe | 10 | 10.4 | 23.5 | PIC 7 |

| TM14DM1800U | Ti/Mo | 14.2 | 9 | 21 | PIC 5 |

| ZZ14DM2100U | Zr/ZrAl | 14.2 | 9 | 21 | PIC 5 |

| ZZ14DM2100U-C | Zr/ZrAl | 14.2 | 9 | 21 | PIC 5 |

| ZZ14DM2100U-C2 | Zr/ZrAl | 14.2 | 9 | 21 | PIC 5 |

| ZZV14DM2800U-C | Zr/Zr-V-Fe | 14.2 | 9 | 21 | PIC 5 |

| ZZV16DM5000U-C | Zr/Zr-V-Fe | 16 | 10 | 17 | PIC 5 |

| ZZV20DM1200U-C | Zr/Zr-V-Fe | 20 | 3.5 | PIC 9 | |

| ZZV22DM2700U-C | Zr/Zr-V-Fe | 22 | 7 | PIC 8 | |

| ZZV26DM3200U-C | Zr/Zr-V-Fe | 26 | 4.5 | PIC 10 |

Disarankeun kaayaan aktivasina

| Paduan | Aktipkeun Suhu ℃ | Suhu Operasi ℃ | Kurva Sorption has |

| Zr / Zr-V-Fe | 400 - 800 | Suhu Kamar 300 | Grafik 1 |

| Ti / Mo | 400 - 800 | Suhu Kamar 300 | Grafik 2 |

| Zr / ZrAl | 700 - 900 | Suhu Kamar 300 | Grafik 3 |

Grafik1: Kurva Sorpsi Biasa tina Zr / Zr-V-Fe

Aktivasina: 500 ℃ × 10 mnt Nyerep: H2, 25℃, P=4×10-4Pa

Graph2: Kurva Sorpsi Tipikal Ti / Mo

Aktivasina: 500 ℃ × 10 mnt Nyerep: H2, 25℃, P=4×10-4Pa

Graph3: Kurva Sorption has Zr / ZrAl

Aktipkeun: 900 ℃ × 10 mnt Nyerep: H2,25℃, P=4×10-4Pa

Awas

1. Getter disegel kudu disimpen dina lingkungan beresih garing kalayan kalembaban relatif leuwih handap 75% m tur euweuh gas erosive.

2. getter stabil dina hawa, tapi lebu, uap jeung gas erosive wajib dihindari. Pikeun ngumpul getter, sarung tangan serat dilarang sareng sarung tangan lateks disposable disarankeun.

3. getter bakal dipaké dina jangka waktu sanggeus kantong aluminium foil atawa can ieu unsealed.

4.The hawa getter teu kudu leuwih ti 200 ℃ dina hawa, disebutkeun eta bakal timer ignite.

5. Rojongan tina manaskeun getter teu kudu shaken beurat, sarta kudu ati bari las getter lest ragrag-off tina alloy getter. Perhatian husus kudu dibayar pikeun nyingkahan kontak langsung antara lead logam bulistir jeung bahan gettering mana lead asup kana awak getter: kanyataanna ieu bakal ngabalukarkeun sirkuit pondok bahaya.

6. getter bisa nedunan ngan sanggeus eta diaktipkeun. Biasana, kami nyarankeun aktivasina sateuacan ngégél alat sareng alat kedah disegel pas saatos getter diaktipkeun. Salila umur alat, getter tiasa diaktipkeun deui.

7. Waktu jaminan kualitas pikeun getter disegel nyaéta sataun ti tanggal manufaktur.

taros Kami

Produk populér nu patali

Mangga ninggalkeun kami pesen.

Mangga lebetkeun alamat surélék anjeun sarta kami bakal ngabales surélék anjeun.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur