Imveliso

Sintered Porous Getter

Iimpawu kunye nezicelo Sintered Porous Getter is sintered ngazo zonke iintlobo non-evaporable getter alloys kubushushu obuphezulu. Ibonakaliswe kubushushu obuphantsi bokuvula, izinga eliphezulu lokufumana, umthamo omkhulu we-sorption, ukubumbana okulungileyo, kunye namasuntswana akhululekileyo. I-Sintered Porous Getter yethu i...

Inkcazo

Sayina

Iimpawu kunye nezicelo

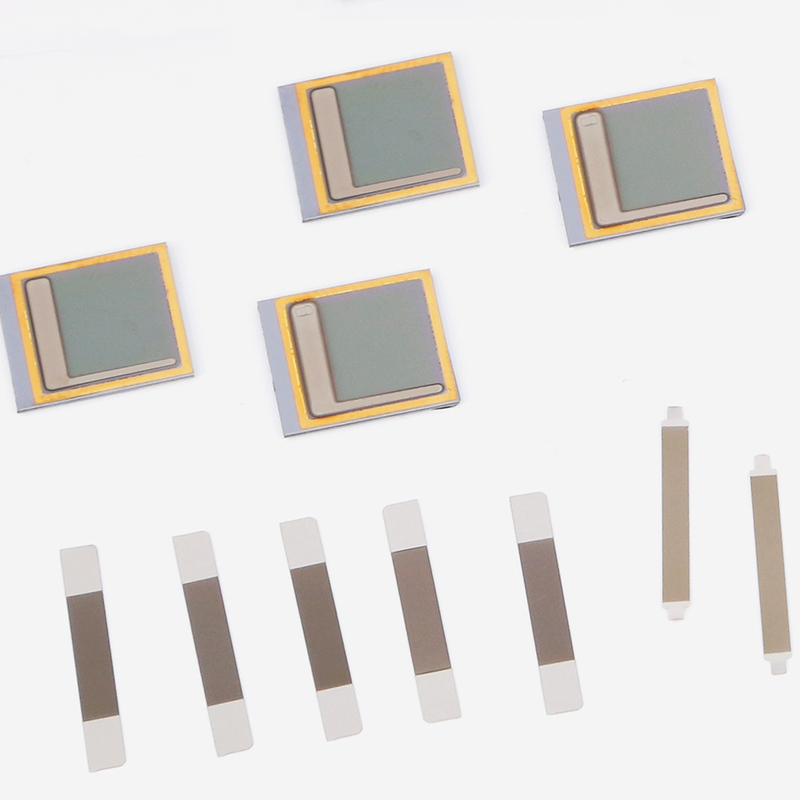

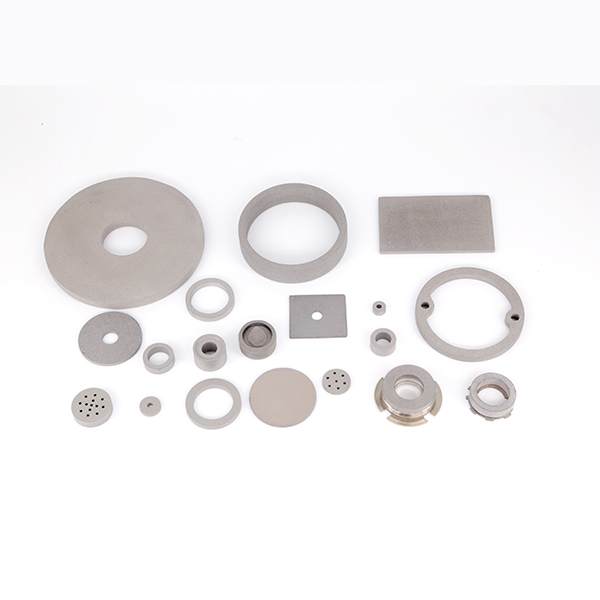

I-Sintered Porous Getter is sintered ngazo zonke iintlobo ze-non-evaporable getter alloys kubushushu obuphezulu. Ibonakaliswe kubushushu obuphantsi bokuvula, izinga eliphezulu lokufumana, umthamo omkhulu we-sorption, ukubumbana okuhle, kunye namasuntswana akhululekileyo. I-Sintered Porous Getter yethu yongezwa nge-activator esebenzayo kunye ne-anti-sintering arhente ukuze kuphuculwe ukusebenza kwayo. Ubungakanani bayo kunye nokubunjwa kunokwenziwa ngokweemfuno zabathengi. Iyakwazi nokuthwala isifudumezisi ukuze ikwazi ukusetyenziswa apho ingenako ukusetyenziswa ngamaza aphezulu okanye ngemitha yobushushu. I-getter isetyenziswa kwi-IR detector Dewar, X-Ray iityhubhu, njalo njalo.

Iimpawu ezisisiseko kunye neDatha ngokubanzi

1.Akukho Uhlobo lwe-heater

| Uhlobo | O.D.(mm) | L.D.(mm) | H(mm) | Izishwankathelo |

| TM7D260X | 6.9 | 3.1 | 3.1 | I-PIC 1 |

| TM8D150X | 7.9 | 3.6 | 1.25 | I-PIC 1 |

| TM8D240X | 8 | 2 | 1.8 | I-PIC 1 |

| TM10D620X | 9.9 | 4.9 | 3.6 | I-PIC 1 |

| TM10D660X | 10.5 | 6.1 | 3.85 | I-PIC 1 |

| TM10D710X | 10 | 6.1 | 4.9 | I-PIC 1 |

| TM12D360X | 12 | 8 | 2 | I-PIC 1 |

| TM12D450X | 11.9 | 5.3 | 1.7 | I-PIC 1 |

| TM12D720X | 12 | 8 | 4 | I-PIC 1 |

| TM12D940X | 12.35 | 7.1 | 3.9 | I-PIC 1 |

| TM13D1030X | 12.6 | 8.8 | 5.5 | I-PIC 1 |

| TM13D1880X | 12.5 | 5.9 | 7.6 | I-PIC 1 |

| TM15D400X | 14.9 | 9.1 | 1.3 | I-PIC 1 |

| TM15D950X | 15 | 10 | 3.5 | I-PIC 1 |

| TM15D1300X | 15 | 8.5 | 3.9 | I-PIC 1 |

| TM15D1420X | 15 | 8.5 | 4 | I-PIC 1 |

| Umfanekiso we-TM15P1480X | 15 | / | 4 | I-PIC 2 |

| TM16D870X | 15.8 | 5.3 | 1.7 | I-PIC 1 |

| TM18D2350X | 17.9 | 8.1 | 4 | I-PIC 1 |

| TM19D2250X | 19 | 10.2 | 3.8 | I-PIC 1 |

| TM20D1410X | 20 | 6.3 | 1.7 | I-PIC 1 |

| TM21D1250X | 21 | 15 | 2.5 | I-PIC 1 |

| TM21D2200X | 21 | 14 | 4 | I-PIC 1 |

| TM25D1930X | 24.9 | 6.2 | 1.7 | I-PIC 1 |

| TM25D5700X | 24.8 | 14.2 | 6 | I-PIC 1 |

| TM26D7780X | 25.85 | 10.2 | 6 | I-PIC 1 |

| TM28D6820X | 27.6 | 14.3 | 5.3 | I-PIC 1 |

| TM32D6650X | 31.7 | 21.3 | 6 | I-PIC 1 |

| TM45D8000X | 45 | 39 | 10 | I-PIC 1 |

2.Ngohlobo lwe-heater

| Uhlobo | Ingxubevange | O.D.(mm) | L2(mm) | L1(mm) | Izishwankathelo |

| ZZV1IM10H-C | Zr/Zr-V-Fe | 1 | 4 | 12 | I-PIC 3 |

| I-ZZV2IM40H-C | Zr/Zr-V-Fe | 2 | 4 | 10 | I-PIC 3 |

| I-ZZV2IM70H-C | Zr/Zr-V-Fe | 1.85 | 7.9 | 20 | I-PIC 3 |

| I-ZZV2IM70HTL-C | Zr/Zr-V-Fe | 1.8 | 7.4 | 18 | I-PIC 4 |

| ZZV3IM100H-C | Zr/Zr-V-Fe | 2.9 | 6.65 | 20.5 | I-PIC 4 |

| ZZV3IM150H-C | Zr/Zr-V-Fe | 3.3 | 7.8 | 20.5 | I-PIC 4 |

| I-ZZV3IM150H-CK | Zr/Zr-V-Fe | 3 | 7.1 | 17 | I-PIC 4 |

| I-ZZV4IM290H-C | Zr/Zr-V-Fe | 4 | 7.9 | 17 | I-PIC 4 |

| I-ZZV4IM290H-CB | Zr/Zr-V-Fe | 4 | 7.1 | 17 | I-PIC 4 |

| I-ZZV4IM290H-CK | Zr/Zr-V-Fe | 4 | 7.8 | 17 | I-PIC 4 |

| ZZV7DM650UT-C | Zr/Zr-V-Fe | 7.8 | 5.5 | 18.5 | I-PIC 7 |

| TM8DM800U | Ti/Mo | 8.4 | 8.5 | 22 | I-PIC 5 |

| ZZV8DM1000U-C | Zr/Zr-V-Fe | 8.2 | 9 | 17.5 | I-PIC 5 |

| ZZV8DIM1000I-C | Zr/Zr-V-Fe | 8.3 | 8.1 | 15.5 | I-PIC 6 |

| I-ZZV10DM1200UT-C | Zr/Zr-V-Fe | 10 | 10.4 | 23.5 | I-PIC 7 |

| TM14DM1800U | Ti/Mo | 14.2 | 9 | 21 | I-PIC 5 |

| ZZ14DM2100U | Zr/ZrAl | 14.2 | 9 | 21 | I-PIC 5 |

| ZZ14DM2100U-C | Zr/ZrAl | 14.2 | 9 | 21 | I-PIC 5 |

| ZZ14DM2100U-C2 | Zr/ZrAl | 14.2 | 9 | 21 | I-PIC 5 |

| ZZV14DM2800U-C | Zr/Zr-V-Fe | 14.2 | 9 | 21 | I-PIC 5 |

| ZZV16DM5000U-C | Zr/Zr-V-Fe | 16 | 10 | 17 | I-PIC 5 |

| ZZV20DM1200U-C | Zr/Zr-V-Fe | 20 | 3.5 | I-PIC 9 | |

| ZZV22DM2700U-C | Zr/Zr-V-Fe | 22 | 7 | I-PIC 8 | |

| ZZV26DM3200U-C | Zr/Zr-V-Fe | 26 | 4.5 | I-PIC 10 |

Iimeko zokuvula ezicetyiswayo

| Ingxubevange | Ukuqalisa iTemp℃ | Ubushushu bokusebenza ℃ | IiCwave zoHlulo eziQhelekileyo |

| Zr / Zr-V-Fe | 400 - 800 | Ubushushu beGumbi 300 | Igrafu 1 |

| Ti / Mo | 400 - 800 | Ubushushu beGumbi 300 | Igrafu 2 |

| Zr / ZrAl | 700 - 900 | Ubushushu beGumbi 300 | Igrafu 3 |

Umzobo1: IiCwave zoHlulo eziQhelekileyo ze Zr/Zr-V-Fe

Ukuqaliswa:500℃×10 imiz Uhluzo:H2, 25℃, P=4×10-4Pa

Umzobo2: IiCwave zoHlulo eziQhelekileyo ze Ti/Mo

Ukuqaliswa:500℃×10 imiz Uhluzo:H2, 25℃, P=4×10-4Pa

IGraph3: IiCwave zokuHluba eziQhelekileyo zeZr/ZrAl

Ukuqaliswa:900℃×10 imiz Uhluzo:H2,25℃, P=4×10-4Pa

Isilumkiso

1. Igeta etywiniweyo iya kugcinwa kwindawo ecocekileyo ecocekileyo kunye nokufuma okungaphantsi kwe-75%m kwaye akukho zigesi ezikhukulayo.

2. I-getter izinzile emoyeni, kodwa uthuli, umphunga kunye nerhasi erosive iya kuphetshwa. Ukudibanisa i-getter, iiglavu zefiber azivumelekanga kwaye iiglavu zelatex ezilahlwayo ziyacetyiswa.

3. I-getter iya kusetyenziswa kwangethuba emva kwebhegi yefoyile yealuminiyam okanye itoti ingavalwa.

4.Iqondo lobushushu le-getter aliyi kuba ngaphezu kwe-200℃ emoyeni, kungenjalo liya kuzitshisa.

5. Inkxaso ye-heater ye-getter ayiyi kushukunyiswa kakhulu, kwaye iya kuqaphela ngelixa i-welding i-getter hleze ukuwa kwe-alloy ye-getter. Ingqwalasela eyodwa kufuneka ihlawulwe ukunqanda naluphi na unxibelelwano oluthe ngqo phakathi kweentambo zetsimbi kunye nemathiriyeli yokufumana apho iinkokeli zingena kumzimba we-getter: enyanisweni oku kunokubangela iisekethe ezimfutshane eziyingozi.

6. I-getter ingenza kuphela emva kokuba ivuliwe. Ngokwesiqhelo, sicebisa ukuba kusebenze phambi kokutywinwa kwesixhobo kwaye isixhobo siya kutywinwa kwakamsinya emva kokuba i-getter ivuliwe. Ngethuba lokuphila kwesixhobo, i-getter ingaphinda isebenze.

7. Ixesha lesiqinisekiso somgangatho we-getter etywiniweyo ngunyaka omnye ukusuka kumhla wokwenziwa.

Qhagamshelana nathi

Iimveliso ezinxulumeneyo ezidumileyo

Nceda usishiyele umyalezo.

Nceda ufake idilesi ye-imeyile kwaye siya kuphendula kwi-imeyile yakho.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur