Imveliso

Abafumana ifilimu abancinci

Iimpawu kunye nezicelo Le mveliso yifilimu encinci ye-titanium okanye i-zirconium alloy ene-microstructure ephuculweyo enokuthi isebenze kuluhlu olubanzi lobushushu. Emva kokusebenza, inokufunxa iigesi ezingcolileyo ezifana ne-hydrogen, umphunga wamanzi, i-carbon monoxide, i-carbon dioxide kunye nezinye izinto ezingcolileyo ...

Inkcazo

Sayina

Iimpawu kunye nezicelo

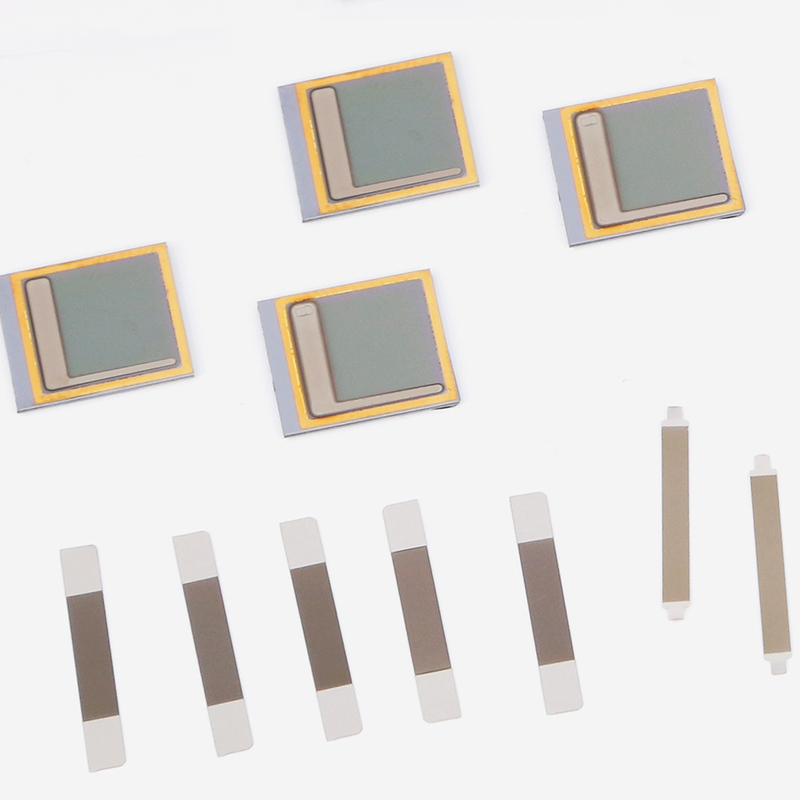

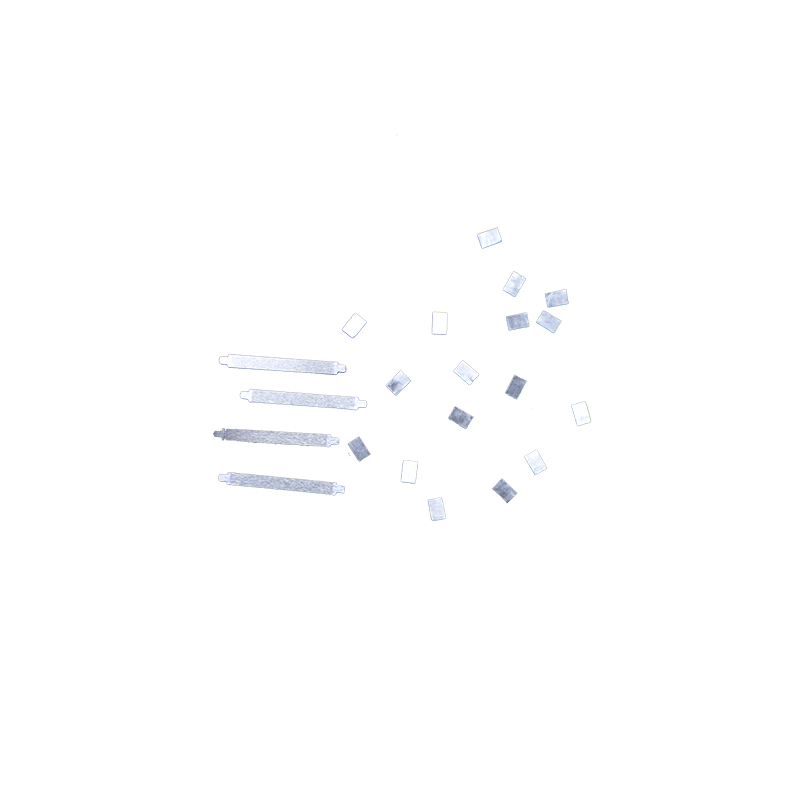

Le mveliso yifilimu encinci ye-titanium okanye i-zirconium alloy ene-microstructure ephuculweyo enokuthi isebenze kuluhlu olubanzi lobushushu. Emva kokusebenza, inokuthatha iigesi ezingcolileyo ezifana ne-hydrogen, umphunga wamanzi, i-carbon monoxide, i-carbon dioxide kunye nezinye iigesi ezingcolileyo ngaphandle kwegesi ye-inert kwindawo yokucoca, kwaye iphucule kwaye igcine i-vacuum ngaphakathi kwesixhobo. Ineempawu zomthamo omkhulu wokuphefumlela, akukho masuntswana, kunye nobushushu obuphantsi bokuvula. Inokusetyenziswa ngokubanzi kwizixhobo ezahlukeneyo ze-MEMS ezifana ne-infrared sensors kunye ne-Micro gyroscope. Ii-alloys ze-getter ezahlukeneyo ziyafumaneka kwiinkqubo ezahlukeneyo ze-encapsulation.

Iimpawu ezisisiseko kunye neDatha ngokubanzi

Ulwakhiwo

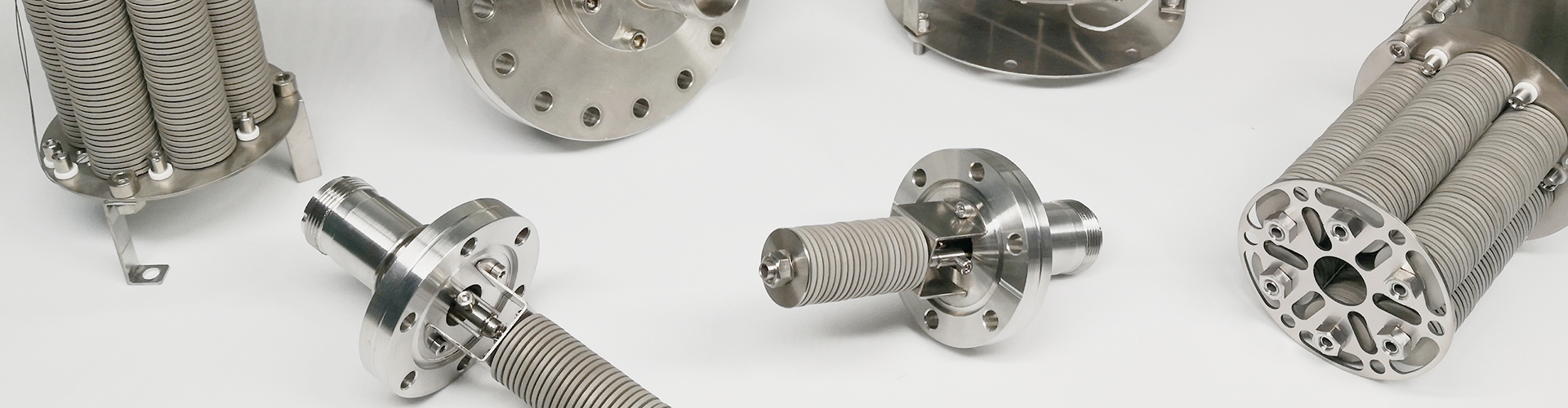

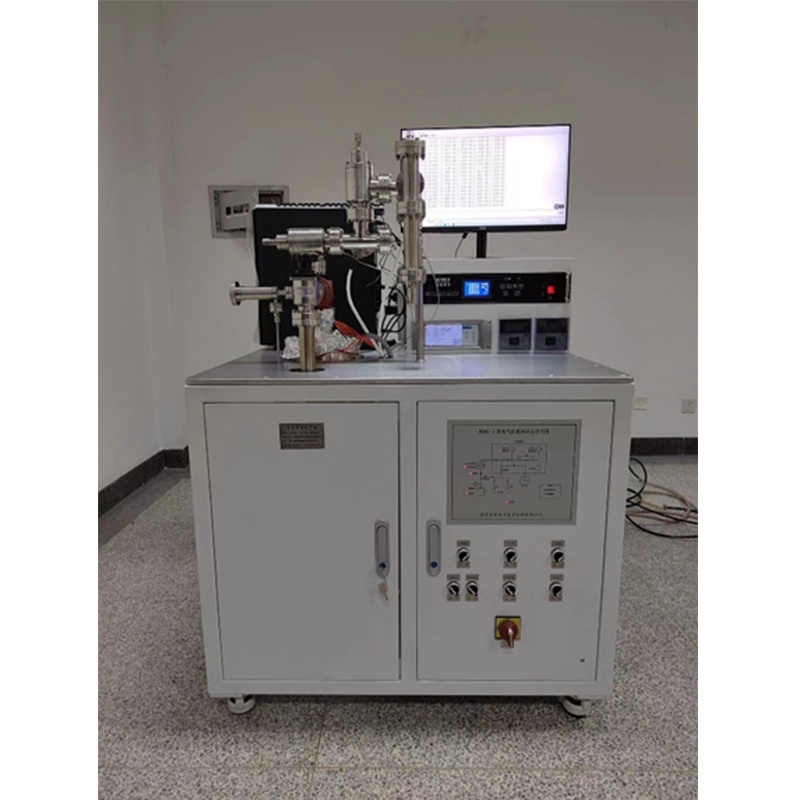

Isakhiwo esiqhelekileyo semveliso yintsimbi engenasici kunye nobukhulu be-microns ezingama-50 njengomthwali, kwaye ubuso bufakwe kumacala omabini, kunye nobukhulu befilimu malunga ne-1.5 microns. Ubume bobungakanani bunokwenziwa ngokwezifiso ngokweemfuno zomsebenzisi. Inokuthi ifakwe ngendlela yeefilimu ezibhityileyo kumphezulu we-wafer okanye iipleyiti ezahlukeneyo zetsimbi kunye namaqokobhe e-ceramic.

Umthamo woHlulo

Emva kokuba imveliso ivuliwe kwivacuum ephezulu eguquguqukayo engaphantsi kwe-1E-3Pa, inokuba namandla okufunxa, kwaye emva kokupholisa kwiqondo lobushushu begumbi, isenakho ukubhengeza iigesi ezahlukeneyo ezisebenzayo. Njengoko ubushushu bokusebenza bukhula, amandla okukhuthaza akhula ngokuthe ngcembe. Imveliso ifudunyezwa kwiqondo lokushisa eliphezulu lokusebenzisa i-30min, kunye nomthamo we-adsorption we-CO emva kokupholisa mkhulu kune-0.06Pa· L / cm2. Xa ubushushu bokusebenza budlula ubushushu obuphezulu bokusebenza, ukusebenza kwe-inhalation enye emva kokupholisa kuyancipha.

Xa imveliso iqhutywe ngokufudumeza kwi-vacuum ephantsi, iigesi ezisebenzayo kwindawo ziqala ukuxutywa ngexesha lokufudumala. Kwiigesi ezahlukeneyo, isantya sokufunxa kunye nomthamo wahlukile. Kwiqondo lokushisa elithile kwaye ngaphakathi koluhlu lwamandla okufunxa ngokupheleleyo, izinga lokuqala lokufunxa likhawuleza, kwaye emva koko liya kuba lincinci kwaye lincinci; Xa ubushushu buphakanyiswa kwakhona, izinga lokufunxa linyuswa kwakhona kwaye liphinde lincitshiswe kwakhona. Emva kokupholisa, ukuba imveliso inomthamo oshiyekileyo wokufunxa kuxhomekeke kuhlobo lwerhasi esebenzayo eyifunxayo kunye nomthamo wokuphefumla.

Iimeko zokuvula ezicetyiswayo

Ngowona msebenzi ubalaseleyo, kucetyiswa ukuba kuvuleleke kwindawo eguquguqukayo yevacuum ephezulu engaphantsi kwe-1E-3Pa, kwaye iimeko ezicetyiswayo zokuvula ifilimu nganye ziboniswa kolu luhlu lulandelayo:

| Izinto zefilimu | Ubushushu kunye nexesha(℃×min) |

| TP | 450×30 |

| I-TZC | 300×30 |

| I-TZCF | 400×30 |

Isilumkiso

Ijiko lokufudumeza langoku-lokuvula ubushushu obubonelelwe kwiNkcazo yeMveliso ivavanywa yimveliso ejingayo kwi-vacuum, kwaye eyona nto isebenzayo ngoku ngokuchasene nobushushu ixhomekeke ikakhulu kwilahleko yobushushu emva kokuba imveliso ithengiswe ngaphakathi kwisixhobo. Ngenxa yokuqhutyelwa kokushisa kwendawo ye-welding, ubushushu becandelo elidibeneyo liphantsi kakhulu kunokushisa kwendawo ephakathi kwemveliso.

Ngexesha lokusebenza, i-getter iya kukhupha i-hydrogen e-soluble ngaphakathi ngaphakathi. Ukuba kukho amanzi kwindawo engqongileyo, ioksijini emanzini iya kulungiswa yi-getter, kwaye i-hydrogen elemental iya kuguqulwa ibe yigesi ye-hydrogen ukuze ikhutshwe. Kwindawo evaliweyo, emva kokupholisa, ingaba le nxalenye ye-hydrogen inokuthatyathwa ngokupheleleyo yi-getter ixhomekeke kuhlobo kunye nesixa segesi esithathayo ngexesha lokusebenza.

Qhagamshelana nathi

Iimveliso ezinxulumeneyo ezidumileyo

Nceda usishiyele umyalezo.

Nceda ufake idilesi ye-imeyile kwaye siya kuphendula kwi-imeyile yakho.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur