Umkhiqizo

Abatholi amafilimu abancane

Izici Nezicelo Lo mkhiqizo ifilimu elizacile le-titanium noma i-zirconium alloy enesakhiwo esincane esithuthukisiwe esingasebenza phezu kwezinga lokushisa elibanzi. Ngemva kokwenza kusebenze, ingakwazi ukumunca amagesi angcolile njenge-hydrogen, umhwamuko wamanzi, i-carbon monoxide, i-carbon dioxide nezinye izinto ezingahlanzekile...

Incazelo

Sayina

Izici kanye nezicelo

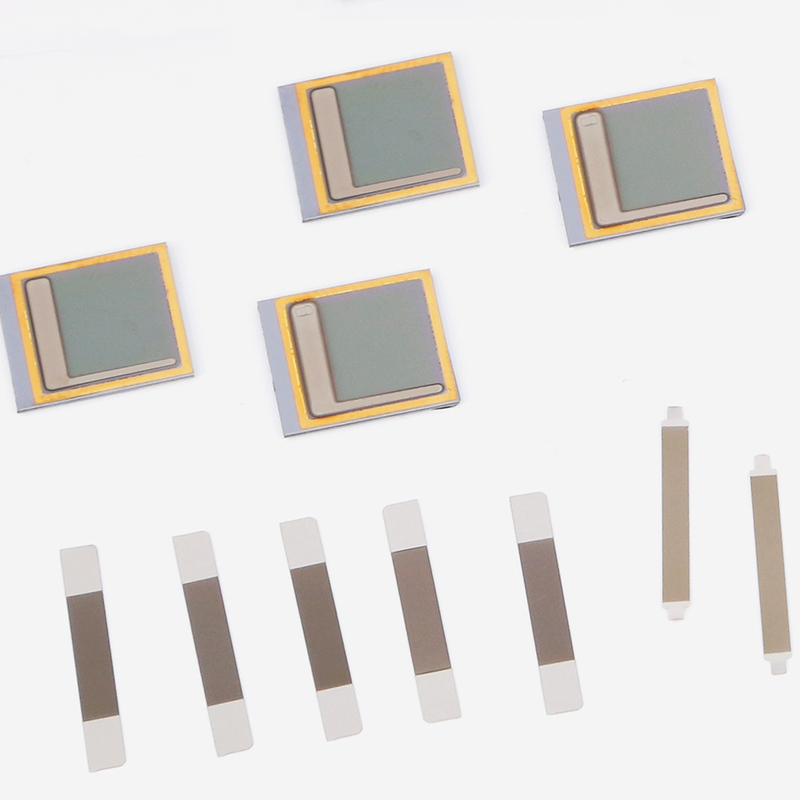

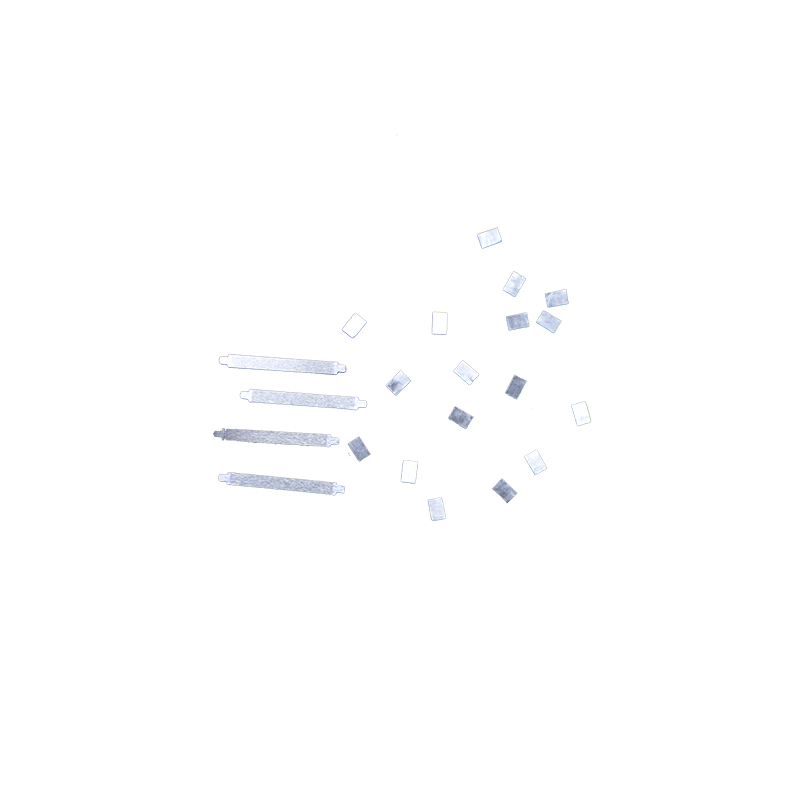

Lo mkhiqizo uyifilimu elincanyana le-titanium noma i-zirconium alloy ene-microstructure elungiselelwe engenziwa isebenze phezu kwebanga lokushisa elibanzi. Ngemva kokwenza kusebenze, ingakwazi ukumunca amagesi angcolile njenge-hydrogen, umhwamuko wamanzi, i-carbon monoxide, i-carbon dioxide namanye amagesi angcolile ngaphandle kwe-inert gas endaweni ye-vacuum, futhi ithuthukise futhi igcine i-vacuum ngaphakathi kwedivayisi. Inezici zomthamo omkhulu wokuphefumula, azikho izinhlayiya, nezinga lokushisa eliphansi lokusebenzisa. Ingasetshenziswa kabanzi kumadivayisi ahlukahlukene we-MEMS njengezinzwa ze-infrared ezingapholisiwe kanye ne-Micro gyroscope. Ama-getter alloys ahlukene ayatholakala ngezinqubo ezahlukene ze-encapsulation.

Izimpawu Eziyisisekelo kanye Nedatha Ejwayelekile

Isakhiwo

Isakhiwo esivamile somkhiqizo siyinsimbi engagqwali enogqinsi lwama-microns angu-50 njengesithwali, futhi ubuso bumbozwe nhlangothi zombili, nobukhulu befilimu obungaba ngu-1.5 microns. Usayizi womumo ungenziwa ngezifiso ngokuya ngezidingo zomsebenzisi. Ingafakwa futhi ngendlela yamafilimu amancanyana ebusweni bewafa noma amapuleti ekhava ensimbi ahlukahlukene namagobolondo e-ceramic.

Amandla Wokuhlunga

Ngemuva kokuthi umkhiqizo ucushwe ku-vacuum ephezulu eguqukayo engaphansi kuka-1E-3Pa, ungaba nekhono lokumunca, futhi ngemva kokupholisa ekamelweni lokushisa, usenamandla okukhangisa amagesi asebenzayo ahlukahlukene. Njengoba izinga lokushisa lokuqalisa likhula, amandla okuphefumula akhula kancane kancane. Umkhiqizo ushiswa ngezinga lokushisa elilungile lokusebenzisa i-30min, futhi umthamo we-adsorption we-CO ngemva kokupholisa mkhulu kuno-0.06Pa· L/cm2. Uma izinga lokushisa lokuqalisa lisebenza lidlula izinga lokushisa elilungile lokuvula, ukusebenza kokuhogela okukodwa ngemva kokupholisa kuyancishiswa.

Lapho umkhiqizo ucushiwe ngokufudumeza ku-vacuum ephansi, amagesi asebenzayo emvelweni aqala ukumuncwa ngesikhathi sokushisa. Ngamagesi ahlukene, isivinini sokumuncwa kwawo kanye nomthamo kuhlukile. Ezingeni elithile lokushisa nangaphakathi kobubanzi bomthamo ophelele wokumunca, izinga lokumunca lokuqala liyashesha, bese lizohamba kancane futhi kancane; Uma izinga lokushisa liphakanyiswa futhi, izinga lokumunca liyakhuphuka futhi bese lincishiswa futhi. Ngemva kokupholisa, ukuthi umkhiqizo unawo yini amandla okumunca insalela kuncike ohlotsheni lwegesi esebenzayo ewudonsayo kanye nenani lokuhogela.

Izimo zokuvula ezinconyiwe

Ukuze usebenze kahle kakhulu, kusebenze ku-vacuum ephezulu eguqukayo engaphansi kuka-1E-3Pa kuyanconywa, futhi izimo ezinconyiwe zokuvula izinto zefilimu ngayinye ziboniswa ohlwini olulandelayo:

| Indaba Yefilimu | Izinga lokushisa nesikhathi(℃×min) |

| I-TP | 450×30 |

| I-TZC | 300×30 |

| I-TZCF | 400×30 |

Isexwayiso

Ijika lezinga lokushisa elisebenza manje lokushisisa elinikezwe Ekucacisweni Komkhiqizo lihlolwa umkhiqizo olenga endaweni engenalutho, futhi ukusebenza kwangempela kwamanje ngokumelene nezinga lokushisa kuncike kakhulu ekulahlekeni kokushisa ngemva kokuba umkhiqizo usudayisiwe ngaphakathi kwedivayisi. Ngenxa yokushisa kokushisa kwesikhundla se-welding, izinga lokushisa lengxenye ehlanganisiwe liphansi kakhulu kunokushisa kwengxenye ephakathi yomkhiqizo.

Ngesikhathi sokusebenza, i-getter izokhipha i-hydrogen encibilikayo ngaphakathi. Uma kunamanzi endaweni ezungezile, umoya-mpilo osemanzini uzolungiswa yi-getter, futhi i-hydrogen eyisisekelo izoguqulwa ibe yigesi ye-hydrogen ezokhishwa. Esikhaleni esivalekile, ngemva kokupholisa, ukuthi le ngxenye ye-hydrogen ingamuncwa ngokuphelele yini i-getter kuncike ohlotsheni kanye nenani legesi elilibambayo ngesikhathi lisebenza.

Xhumana nathi

Imikhiqizo ehlobene edumile

Sicela usishiyele umlayezo.

Sicela ufake ikheli lakho le-imeyili futhi sizophendula i-imeyili yakho.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur